Product specifications

Manufacturers: Diosna, Rademaker, Heinen and Niverplast

Year: 2017

Capacity: Up to 40.000 croissant per hour

Location: Germany

Out of production, still installed

Consisting of:

Diosna mixing station:

• 2 pc. Diosna WV240 E double wendel mixers, bottom discharge, moving dough trolley

• Diosna bowl lifter

Rademaker laminating line:

• Dough hopper on platform

• LSS-Dough extruder

• Satellite head

• Longitudinal cutting station

• Rest dough brush

• Rest dough conveyor

• Fat pump including fat block feeding conveyor

• Folding belts

• Driven pressure roller

• Satellite head

• Laminating by swing

• Driven pressure roller

• Satellite head

• Laminating by belt

• Driven pressure roller

• Satellite head

• Up going conveyor towards cooling and resting belts

• 30 minutes cooling, 60 minutes resting in elevated isolated cabinet

• Down going conveyor

• Satellite head

• Cross roller

• 2 pc. Gauging station

• Multiple flour dusters with automatic filling system

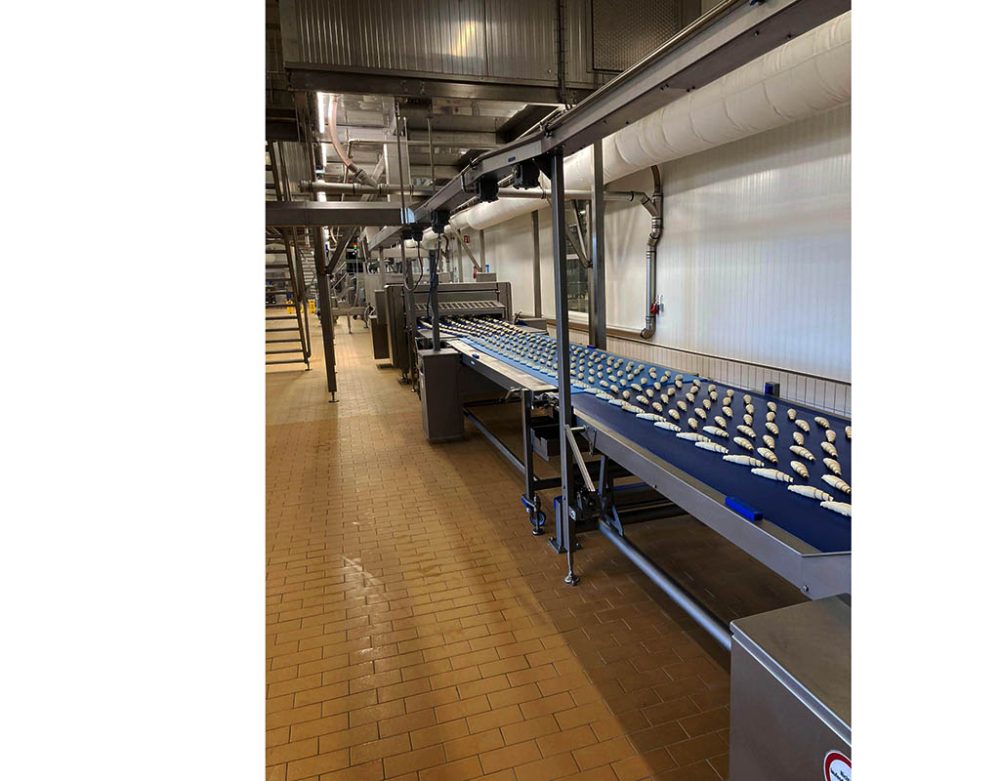

Rademaker croissant and universal line:

• Flour removal brush

• Longitudinal cutting station

• Spreading belt

• Rest dough removal system

• Turning station

• Dosing system for filled croissants

• Special cutter for slices of ham

• Croissant coiling machine for filled and unfilled croissants

• Croissant bending tool

• Moving guillotine

• Hinged pressure rollers

• Longitudinal cutting station with trimming knife

• Rest dough removal brush with rest dough conveyor

• Water sprayer

• Location for filling station

• Universal strewer

• 2 pc. Folding station

• Top running conveyor belt

• 2 pc. Curling station

• Position correction unit

• Driven pressure roller

• Moving guillotine

• Spreading belt

• Guillotine

• 2 pc. Dosing machines

• Various trolleys for tool storage including tools for several products

Heinen double proofing tower:

• Infeed low, outfeed low

• 2 x 36 levels, free height 88 mm

• Air temperature adjustable between 20 and 35 degree’s Celsius

• Humidity adjustable between 55 and 85%

• Including air cooler

• Including integrated cleaning system

• Belt drying unit

Rademaker decoration belt after proofer:

• Water sprayer

• Universal strewer

• Strewing material return system

• 2 pc. Disc sprayer

• Pressure roller

• Water sprayer

• Waterfall strewer for cheese including strewing material return system

• Various conveyor belts

Heinen freezing tower:

• Infeed low, outfeed high

• 36 levels, free height 86 mm

• Plastic belt, 1000 mm in width

• Evaporators for Co²

• Sequential defrosting system

• Integrated cleaning system for cleaning

• Belt drying system

Niverplast Crisp packaging installation:

• Down going conveyor

• Quality check station, checks on sizes, color and black spots, Automatic ejecting of products

• Counting module

• Batching module

• 4 pc. Form and fill machine

• 2 pc. Merging conveyor

• 2 pc. Anritsu x ray machines

• 2 pc. Anritsu checkweigher

• 2 pc. Product ejector

• 2 pc. Spiral conveyor belt

• 2 pc. CPS bag in box packer

• Carton transport conveyors

• Carton box closer

• Anritsu checkweigher for filled carton boxes

• Markem Imaje, box marker, 4 sides

• Carton box ejector

• Carton box erector

Electrical: 3 x 400 V – 50Hz

| Brand | Diosna, Heinen, Niverplast, Rademaker |

|---|---|

| Category | Pastry |

| Year | 2017 |

| Capacity | Up to 40.000 croissant per hour |

| Location | Germany |

| Machine number | 962 |

| In production? | No |

| Sold | Yes |

Benefits of working with us

-

Services to guarantee success

-

20+ years of knowledge and experience

-

High-quality production lines